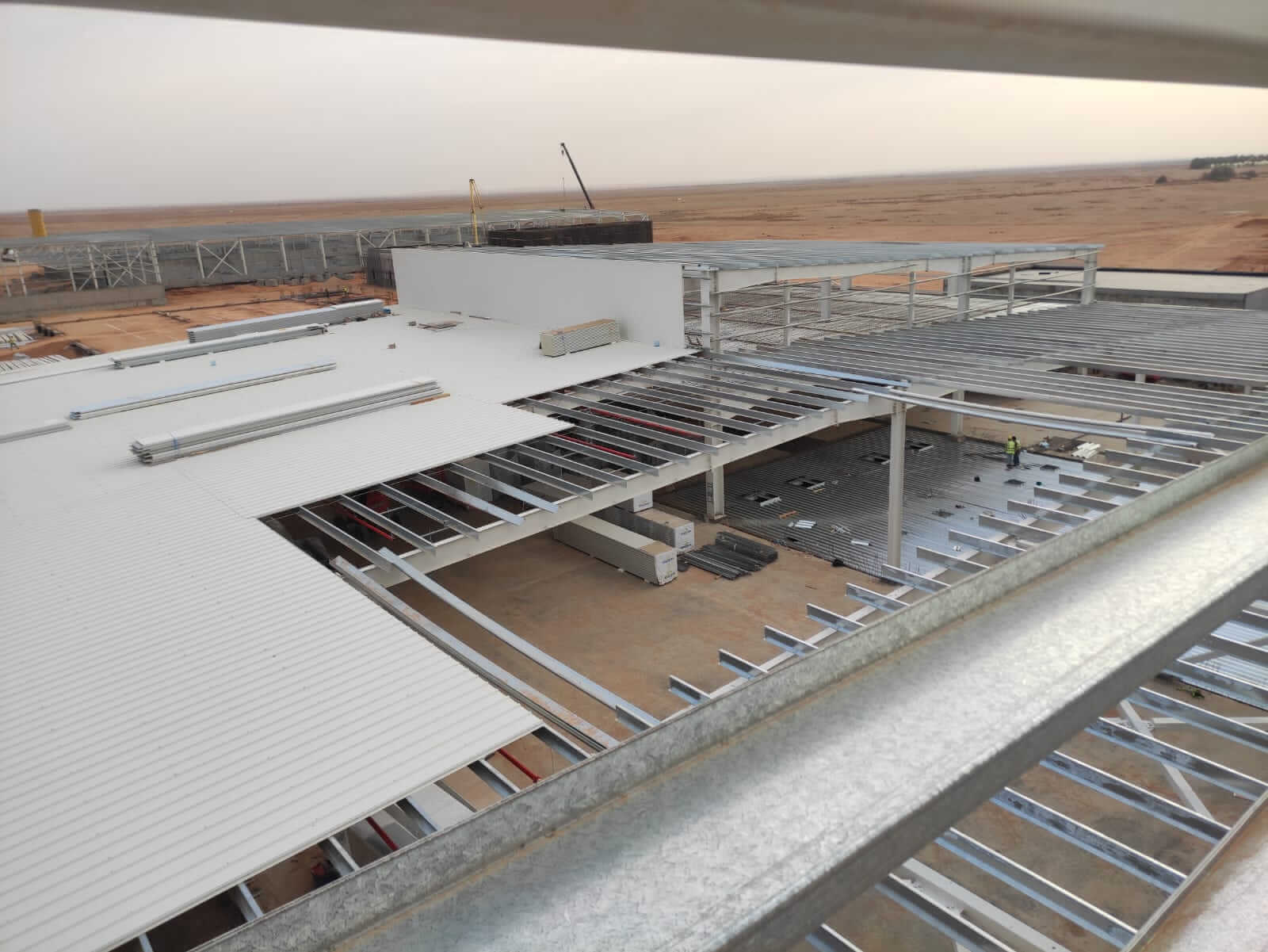

Saudi Arabia’s project pipeline in 2025 remains one of the most active globally, with parallel civil, infrastructure, and industrial packages moving at speed under Saudi Vision 2030. In this environment, procurement is no longer a back-office function—it’s a performance lever.

For site managers and supervisors, the ability to secure bulk supplies quickly, compliantly, and cost-effectively often determines whether crews stay productive, milestones hold, and margins are protected.

From cement and fasteners to PPE and electrical tools, the “everyday” items are the ones that make—or break—daily operations.

Blue Nexus supports contractors across the Kingdom with a bulk-buying model that consolidates demand, stabilizes pricing, reduces lead times, and streamlines documentation. The outcome: fewer stoppages, predictable cash flow, and measurable cost improvements.

Why Bulk Procurement Matters in 2025

Project conditions in KSA reward scale and speed. Bulk purchasing converts fragmented, site-by-site buys into a single, leverageable volume—unlocking lower unit costs, clearer SLAs, and stronger vendor accountability

It also reduces the “hidden” overheads that erode margin: repeat RFQs, emergency shipments, and invoice chaos.

What we see across active sites in 2025:

Lead-time pressure: Multi-site execution increases strain on local supply. Bulk contracting with buffer stock consistently shortens replenishment.

Cost volatility: Material price swings are real; framework pricing and quarterly true-ups smooth the curve.

Compliance scrutiny: Owners and consultants expect clean submittals and traceability—best solved once at scale, not site-by-site.

The Blue Nexus Bulk Sourcing Model

Blue Nexus translates volume into value through an integrated approach built for #LocalProcurement realities in Saudi Arabia:

Demand Consolidation & Forecasting

Aggregate 60–90 days of PR/GRN data to identify A/B/C movers.

Apply variability bands (±10–15%) for real-world swings at site level.

Align replenishment to shift patterns and shutdown windows.

Category Strategies (High-Consumption Lines)

Cement & aggregates: Multi-plant allocation to cut haul distance; indexed pricing with transparent adjustments.

Fasteners & fixings: SKU standardization to reduce substitutions and approval cycles.

PPE & safety: Dual-source critical SKUs; pre-pack kits per crew for faster issuance.

Electrical tools & consumables: Catalog purchasing with reorder points; service exchange for high-wear tools.

Vendor Consolidation with Redundancy

Fewer suppliers, clearer SLAs—while preserving approved alternatives for risk control.

Pre-qualification includes delivery performance, spec adherence, and documentation readiness.

Logistics & Last-Mile Excellence

Staged inventory in Riyadh/Eastern Province; night-before kitting for day-one availability.

Geo-stamped POD and delivery windows that match site access constraints.

Documentation by Design

Unified packs (PO, CoC, MSDS/test reports where applicable) tied to each drop.

Digital audit trail to accelerate inspections and monthly closes.

2025 Performance Snapshot (Representative)

Based on multi-site implementations with tier-1 and tier-2 contractors in KSA, Blue Nexus bulk programs commonly deliver:

Unit-cost reductions: 8–14% across top-50 SKUs via tier pricing and volume breaks.

Lead-time improvement: 30–40% faster average replenishment through buffer stock and pre-kitted drops.

OTIF reliability: 95–98% on catalog lines with penalty-backed SLAs.

Fewer fire-drills: 25–40% reduction in urgent PRs due to stabilized supply of A-movers.

Finance efficiency: 20–35% fewer supplier invoices and disputes after consolidation.

These ranges reflect live operating conditions in 2025 and are influenced by site remoteness, access windows, and category mix.

What Contractors Buy in Bulk (And Why It Matters)

Daily execution depends on predictable availability of high-turn items:

Civil & site: cement, curing compounds, tie-wire, shuttering consumables.

Fasteners: anchors, threaded rods, structural bolts, washers, nuts.

PPE & safety: FR coveralls, helmets, gloves, eyewear, fall-arrest gear.

Electrical: cables, trunking, junction boxes, industrial plugs, lighting spares.

Tools & MRO: grinders, drills, abrasives, sealants, lubricants, welding rods.

When these lines are consolidated, priced, and staged, crews keep moving—and supervisors stop firefighting.

Case Example: Two Cities, One Basket

A contractor running packages in Riyadh and the Eastern Province shifted from spot buys to a Blue Nexus bulk program covering fasteners, PPE, and electrical consumables:

18% price reduction on fasteners via master lots and quarterly true-ups.

Next-day availability for PPE starters and auto-replenishment at minimum stock.

97% OTIF on catalog SKUs; urgent drops fulfilled in <12 hours for 80% of requests.

30% fewer site stoppages linked to material shortages logged by supervisors.

Net effect: milestones held, overtime dropped, and margin leakage slowed.

How Blue Nexus Protects Margins

Aggregation Power: Turning scattered PRs into leverageable volume.

Spec Discipline: SKU normalization reduces errors and rework.

Structured Redundancy: Dual-source critical SKUs to avoid stock-outs.

Proximity Logistics: Cross-dock staging and last-mile reliability.

Data Cadence: Weekly control-tower reporting—usage, OTIF, backorder heat map.

Together, these levers convert procurement from a cost center into a predictable performance system.

Practical Tips for Site Teams in 2025

Identify your A-movers and lock them under framework pricing.

Pre-approve alternates for fasteners, PPE, and tool brands to maintain continuity.

Use catalog buying for repeat lines; reserve RFQs for complex or new items.

Treat documentation as an output of the process—not an afterthought.

Stage buffer stock before shutdowns and critical lifts.

Conclusion: Bulk Buying = Better Margins

In Saudi Arabia’s high-velocity project market, bulk buying is not just cheaper—it’s smarter. By consolidating demand, stabilizing prices, and engineering last-mile delivery, Blue Nexus helps contractors keep crews productive, protect schedules, and safeguard margins. Whether you’re supplying a single industrial site or coordinating multiple packages across regions, a bulk program with Blue Nexus turns everyday materials into a strategic advantage.

Ready to turn procurement into performance? Let’s build your bulk basket—and your margin plan.